What is Plywood Companies?

Plywood is crucial in construction, furniture, and manufacturing. Its availability and quality come from plywood companies’ efforts. These entities include manufacturers, suppliers, factories, and companies. They are central to a global industry. This industry values innovation, sustainability, and efficiency. Advanced manufacturing techniques are integrated. Environmental stewardship is a commitment. Plywood companies meet the demand for durable materials. These materials are versatile and eco-friendly. They are essential for building worldwide.

The Backbone of Modern Construction and Manufacturing

The Evolution of Plywood Manufacturing

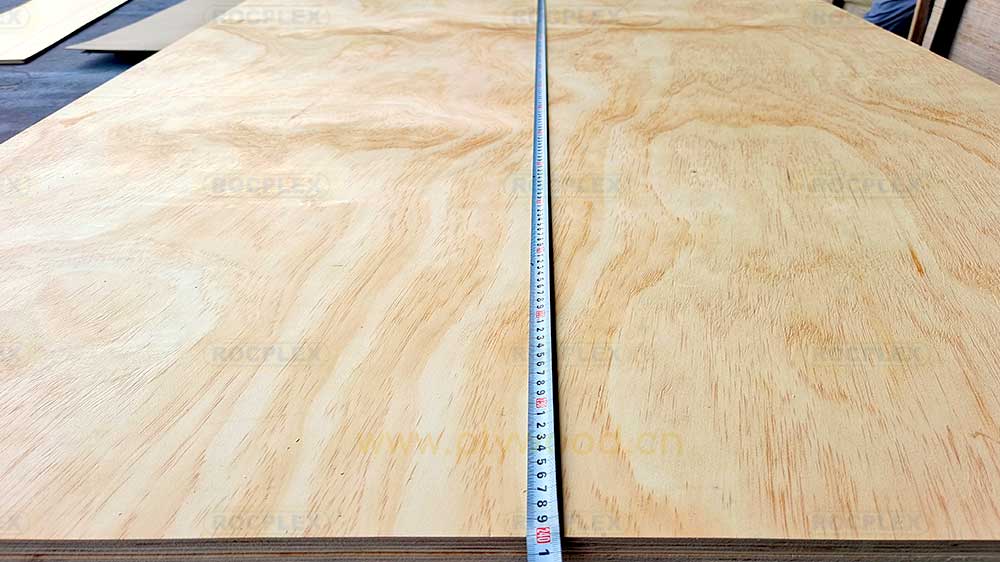

The journey of plywood from log to laminated boards is a testament to the plywood manufacturer’s expertise and technological advancement. State-of-the-art machinery and processes ensure the transformation of raw wood into high-quality plywood, ready for a multitude of uses. This evolution is not just about production efficiency but also about sustainability. Leading plywood factories now employ practices that maximize yield from each log, reducing waste and promoting forest conservation.

Global Supply Dynamics and Plywood Suppliers

In the realm of construction and manufacturing, the reliability of supply chains is paramount. Plywood suppliers play a critical role in ensuring the smooth flow of materials across borders, adapting to the complexities of global logistics. Their expertise in navigating regulatory landscapes and market fluctuations ensures that plywood remains accessible worldwide, supporting industries from construction to cabinetry.

Sustainability and Environmental Responsibility

Amid growing environmental concerns, the plywood industry has been proactive in embracing sustainable practices. From sourcing wood from certified forests to implementing recycling programs, plywood companies are at the forefront of environmental stewardship. These initiatives not only contribute to the sector’s sustainability but also resonate with consumers increasingly seeking eco-friendly products.

Innovation Driving the Plywood Industry Forward

Innovation is the lifeblood of plywood companies, propelling the industry into new realms of possibility. From the development of stronger, lighter plywood variants to the integration of smart technologies in manufacturing processes, these advancements redefine what plywood can do. As the industry continues to innovate, plywood becomes an even more indispensable material in modern design and construction.

Looking Ahead: The Future of Plywood

The future of plywood companies is intrinsically linked to the trends shaping the global economy and environment. As urbanization accelerates and the call for sustainable building materials grows louder, the plywood industry is poised for transformative change. Advances in manufacturing technology, coupled with a deepening commitment to sustainability, herald a new era for plywood companies. In this dynamic landscape, adaptability and innovation will be key to meeting the challenges and seizing the opportunities of tomorrow.

Navigating Challenges and Opportunities

The Impact of Global Market Trends on Plywood Companies

Plywood companies are often impacted by global market trends. Currency fluctuations affect them. So do trade policies and international disputes. These factors influence plywood’s cost and availability. Companies must be agile and strategic. Adapting to market shifts is essential. Successful suppliers anticipate these changes. They adjust sourcing and distribution strategies. This agility is a hallmark of success in the plywood industry.

Technological Advancements in Plywood Production

Technological innovation continues to revolutionize plywood production, enabling companies to enhance quality, efficiency, and environmental performance. Digital technologies are being adopted in the industry. AI and IoT monitor and optimize manufacturing. This move signals a shift towards smart factories. These advancements boost productivity. They also reduce energy consumption. Waste reduction is another benefit. This aligns with sustainability goals.

Meeting the Demand for Customization

In an era where customization is king, plywood supplier are increasingly offering bespoke solutions to meet specific customer needs. Whether it’s tailored dimensions, specialized finishes, or engineered properties for unique applications, the ability to customize products is becoming a competitive differentiator. This trend towards customization reflects the industry’s responsiveness to evolving market demands and the diverse needs of sectors ranging from construction to furniture design.

Strengthening Sustainability Practices

Advancing Towards Carbon Neutrality

As the global community intensifies its focus on combating climate change, plywood companies are under increased pressure to reduce their carbon footprint. Efforts to achieve carbon neutrality involve optimizing energy use, embracing renewable energy sources, and enhancing the sustainability of supply chains. Moreover, the industry’s investment in reforestation and responsible wood sourcing practices demonstrates a commitment to not just minimizing environmental impact but actively contributing to ecological restoration.

The Role of Certification and Eco-Friendly Labels

Certification schemes and eco-friendly labels play a pivotal role in guiding consumers towards sustainable plywood products. By adhering to standards set by organizations like FSC and PEFC, plywood companies can assure customers of the sustainability and ethical sourcing of their products. These certifications not only help in building trust with eco-conscious consumers but also encourage the industry as a whole to uphold high environmental standards.

The Plywood Industry’s Contribution to Global Housing and Infrastructure

Addressing the Global Housing Crisis

Plywood companies are at the vanguard of addressing the global housing crisis by providing affordable, durable, and sustainable building materials. The versatility and strength of plywood make it an ideal choice for innovative housing solutions, including modular homes and temporary shelters. As the demand for accessible housing continues to grow, plywood companies are uniquely positioned to offer materials that can accelerate construction, reduce costs, and meet the needs of diverse populations.

Infrastructure Development and Plywood

The role of plywood in infrastructure development cannot be overstated. Plywood supports bridge and tunnel construction. It’s vital in disaster-resilient structures. Its strength, flexibility, and affordability make it indispensable. Plywood companies supply high-quality materials. These materials meet strict standards. They contribute to infrastructure development. The result is functional and sustainable infrastructure.

Embracing Digital Transformation and E-commerce

The digital age has ushered in significant changes for plywood companies, with digital transformation and e-commerce becoming increasingly important. The ability to leverage online platforms for sales, customer engagement, and supply chain management is transforming traditional business models. Plywood suppliers and manufacturers who embrace these technologies are finding new ways to reach global markets, improve operational efficiencies, and enhance customer service. This digital shift not only broadens the market reach but also enables companies to respond more swiftly to changing consumer preferences and market demands.

The Growing Importance of Collaborative Partnerships

In today’s interconnected world, collaborative partnerships across industries and borders are becoming a strategic imperative for plywood companies. Partnerships with technology firms, research institutions, and sustainability organizations can drive innovation, improve environmental outcomes, and open up new market opportunities. These collaborations allow plywood companies to leverage external expertise and technologies, enhancing their product offerings and sustainability credentials. As the industry moves forward, the ability to form and maintain strategic partnerships will be crucial in navigating the complexities of the global marketplace.

Plywood and the Circular Economy

The circular economy concept is gaining popularity in the plywood industry. Companies are working to minimize waste. They aim to maximize resource efficiency. Recycling wood waste is one initiative. Developing biodegradable adhesives is another. Designing products for easy disassembly and reuse is also a focus. These actions align with circular economy principles. They support environmental sustainability. Economic benefits also arise. Costs are reduced. New revenue streams emerge from recycled materials. Circular services offer additional opportunities.

Challenges Ahead: Regulatory Compliance and Market Adaptation

As environmental regulations become stricter and consumer expectations shift towards sustainability, plywood companies face the challenge of staying compliant while remaining competitive. Navigating the complex landscape of international standards, certification requirements, and environmental laws requires constant vigilance and adaptability. Furthermore, the industry must continue to innovate in product development and operational practices to meet these evolving demands, ensuring that plywood remains a material of choice in a more sustainable future.

Looking to the Future: Innovation, Sustainability, and Growth

The plywood industry stands at a crossroads, where the path forward is defined by innovation, sustainability, and the ability to adapt to an ever-changing global landscape. Plywood companies that invest in advanced manufacturing technologies, embrace sustainable practices, and foster strong partnerships will be well-positioned to thrive. As the industry continues to evolve, the focus on producing high-quality, environmentally responsible plywood products will not only drive economic growth but also contribute to the well-being of communities and the planet.

Summing Up the Essence of Plywood Companies

The narrative of plywood companies is one of resilience, innovation, and commitment to sustainability. The plywood industry is enhancing its manufacturing processes. It is embracing digital transformation. Sustainability practices are advancing. The industry is ready for 21st-century challenges. The future success of plywood companies depends on several factors. They must adapt. Innovation is key. A focus on sustainability is critical. Environmental stewardship is essential.

FAQs

Which brand is best in plywood?

ROCPLEX brand is best in plywood, known for its quality, durability, and commitment to sustainability.

Who is the largest plywood manufacturer in China?

ROCPLEX plywood manufacturer stands out as a leading player, renowned for its extensive production capabilities and innovative product offerings.

Which country has the best plywood?

Countries with a long-standing tradition of forestry and wood manufacturing, such as Finland, Canada, and Brazil, are often recognized for producing high-quality plywood.

What is the highest quality plywood?

The highest quality plywood is typically graded as A-A, with superior strength, durability, and smooth surfaces, suitable for high-end applications.

Is Chinese plywood good?

Chinese plywood has improved in quality. It has also advanced in sustainability. Many manufacturers follow international standards. They also adhere to certifications. This makes it competitive globally.

Post time: Mar-03-2024