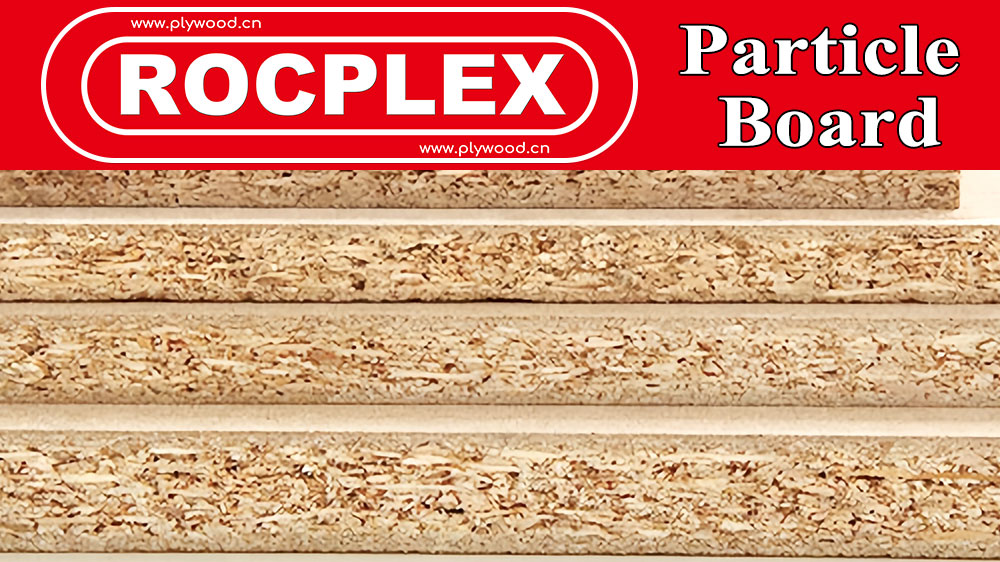

What is Chip Board?

Chip board, also known as particle board or chipboard sheets, is an engineered wood product manufactured from wood chips, sawmill shavings, or even sawdust, bonded together with a synthetic resin or other suitable binder. Typically used in construction, furniture, cabinetry, and flooring, chip board has become a popular choice due to its affordability, versatility, and eco-friendliness. Its production involves compressing the wood particles at high temperatures, resulting in a dense, uniform board.

The Evolution of Chip Board

The Rise of Eco-Friendly Construction Materials

As the construction industry evolves, there is a growing emphasis on sustainability. Chip board, being predominantly made from recycled materials, stands at the forefront of this eco-friendly wave. Its production process not only minimizes waste but also utilizes less energy compared to traditional wood products, making it an environmentally responsible choice.

Technological Innovations in Chip Board Manufacturing

Recent technological advancements have significantly improved the quality and durability of chip board. Innovations in bonding agents and pressing techniques have resulted in particle board that is stronger, more moisture-resistant, and versatile. This has expanded its applications, making it a reliable alternative to traditional wood in various construction scenarios.

Chip Board in Modern Interior Design

Chip boards, particularly in their more refined form as sterling board, have found a place in modern interior design. Its smooth surface and uniform texture make it ideal for veneers and laminates, offering designers a cost-effective yet stylish material choice.

Economic Impact of Chip Board Production

The chipboard industry has seen a notable economic impact, providing cost-effective solutions in the construction and furniture sectors. Its affordability makes it accessible for large-scale projects, while its versatility allows for innovative applications, reducing overall project costs.

Chip Board: A Versatile Material

The Diverse Applications of Chip Board

Chip board’s versatility is one of its strongest assets. From flooring underlayment to furniture manufacturing, its range of uses is vast. The material’s adaptability to different finishes and treatments also makes it a preferred choice for custom projects.

Sterling Board: A Premium Choice

Sterling board, a higher-quality variant of chipboard, offers enhanced durability and moisture resistance. This makes it particularly suitable for outdoor applications, where traditional particle board might not suffice. Sterling board’s superior strength and resilience have made it a top choice for more demanding construction projects.

Chip Board in Green Building Initiatives

Emphasizing sustainability, chip board is often a key component in green building initiatives. Its use in eco-friendly projects underlines the industry’s commitment to reducing environmental impact, fostering a more sustainable approach to construction and design.

Advanced Manufacturing Processes

Innovations in Composite Materials

The development of composite chip boards, incorporating materials like recycled plastics and fiberglass, has led to a new generation of chip boards with enhanced properties. These composites offer greater durability, resistance to moisture and pests, and improved fire-retardant capabilities. Such advancements make chipboard suitable for more demanding applications, including exterior construction and high-moisture environments.

Automation in Production

Automation in chip board manufacturing has streamlined the production process, ensuring consistent quality and reducing costs. Advanced machinery can precisely control factors like temperature and pressure during the production, resulting in a more uniform and reliable product. This automation also enhances worker safety and reduces the environmental impact of the manufacturing process.

Chip Board in Industry Sectors

Chip Board in the Furniture Industry

In the furniture industry, chip board has become a staple due to its affordability and ease of manipulation. It’s particularly favored for flat-pack furniture, where its lightweight nature and ease of assembly are key advantages. With advances in lamination and veneering techniques, particle board furniture can now emulate the look of solid wood at a fraction of the cost.

Use in Construction

Particle board, especially sterling board, is widely used for flooring, wall sheathing, and roofing. Its uniformity ensures a consistent performance, which is crucial in construction applications. The material’s adaptability allows it to be used in various climatic conditions, with specific types designed for enhanced moisture resistance or thermal insulation.

Environmental Impact and Sustainability

Recycling and Reuse

A significant advantage of chip board is its potential for recycling and reuse. Chipboard can be repurposed at the end of its life cycle, reducing waste. This aspect aligns with the growing global emphasis on sustainable construction practices and circular economies.

Chip Board and Carbon Footprint

The use of chip board contributes to a lower carbon footprint in construction and furniture manufacturing. Since it’s made from recycled wood products and requires less energy to produce than traditional wood, chipboard is a more sustainable choice, helping to reduce the overall environmental impact of these industries.

Trends and Future Outlook

The Role of Chip Board in Affordable Housing

As housing demands grow globally, chipboard has emerged as a key material in affordable housing projects. Its cost-effectiveness and ease of use make it ideal for large-scale construction, providing a viable solution for budget-conscious housing initiatives.

Future Innovations

Ongoing research and development promise further improvements in particle board technology. Potential areas of advancement include the integration of smart materials, further enhancements in environmental resilience, and the development of even more sustainable manufacturing processes.

Chip Board in Global Markets

Market Growth and Demand

The global demand for chip board is on the rise, driven by its affordability and versatility. Emerging markets, in particular, are seeing increased use of particle board in construction and furniture manufacturing, contributing to the material’s global market growth.

Export and Import Trends

As a widely used material, chip board sees significant movement in international trade. Countries with advanced wood processing industries are key exporters, while developing nations often emerge as major importers, leveraging chipboard for their growing construction and furniture sectors.

The Aesthetics and Design Flexibility of Chip Board

Customization and Finishing Options

One of the key appeals of chip board is its versatility in design and finishing. With the ability to accept a wide range of finishes – from veneers and laminates to paints and varnishes – chipboard allows for extensive customization. This adaptability makes it a favorite among designers and homeowners looking to achieve a high-end look without the high-end price tag.

The Role of Chip Board in Contemporary Design

In contemporary design, chip board is not just a material of necessity but a choice for aesthetic appeal. Its smooth, uniform surface provides a perfect canvas for innovative design ideas. The recent trend of exposing the raw, textured look of particle board in furniture and interior design highlights its acceptance as a stylish material in its own right.

Health and Safety Standards in Chip Board Use

Emission Standards and Regulations

Health and safety are paramount in the production and use of chip board. Regulations regarding the emission of formaldehyde, a common bonding agent in particle board, have led to the development of low-emission and formaldehyde-free products. These advancements ensure safer indoor air quality and meet stringent health standards in various countries.

Safety in Handling and Installation

While working with chip board, safety precautions are necessary. The material’s composition requires careful handling to avoid splintering and dust inhalation. Adhering to safety guidelines during cutting, installation, and finishing is crucial for both professional builders and DIY enthusiasts.

Chip Board in Educational and Community Projects

Educational Applications

Chip board’s affordability and ease of use make it an excellent material for educational settings. Schools and universities often use chip board in design and architecture courses, allowing students to experiment with construction and fabrication techniques without incurring high material costs.

Community and Non-Profit Initiatives

In community and non-profit projects, chipboard serves as a practical material for building low-cost furniture, community centers, and even temporary housing. Its cost-effectiveness and ease of assembly make it an ideal choice for initiatives with limited budgets.

The Global Perspective

Chip Board’s Impact on International Trade

Chip board plays a significant role in international trade, especially in the construction and furniture sectors. Its global market presence is bolstered by its widespread acceptance and versatility, making it a staple in both developed and emerging economies.

Sustainability Initiatives Worldwide

Globally, the particle board industry is aligning with sustainability initiatives. Efforts to produce eco-friendlier chip boards, such as using more sustainable adhesives and increasing the use of recycled materials, reflect the industry’s commitment to environmental stewardship.

Looking Forward: The Future of Chip Board

Innovations on the Horizon

The future of chip board looks promising with ongoing innovations aimed at enhancing its strength, durability, and environmental footprint. Research into alternative bonding agents, use of renewable fibers, and incorporation of smart technology is set to redefine chip board’s role in construction and design.

The Expanding Role of Chip Board in a Sustainable World

As the world moves towards more sustainable construction and manufacturing practices, chipboard is poised to play a pivotal role. Its evolution from a budget-friendly alternative to a preferred choice for eco-conscious projects underscores its growing significance in a more sustainable future.

Wrapping Up Our Discussion on Chip Board

In closing, the chip board industry stands at a crossroads of innovation, sustainability, and design flexibility. From its humble beginnings as a cost-effective substitute for solid wood, chipboard has evolved into a versatile, eco-friendly material embraced by the construction and design communities. Its future, driven by technological advancements and a commitment to sustainability, is bright and promising, making chipboard a material of choice for the present and the future.

FAQs

What is chip board used for?

Chip board is utilized in furniture, construction, cabinetry, and flooring, offering an economical and adaptable material choice.

What are the positives and negatives of chipboard?

Advantages include cost-effectiveness, versatility, and environmental friendliness; drawbacks are lower strength compared to solid wood and moisture sensitivity.

Is chip board the same as particle board?

Yes, chip board is also known as particle board, referring to the same engineered wood product.

What is stronger chipboard or MDF?

MDF, with its finer particles and higher density, is generally stronger than standard chip board.

Which is cheaper chipboard or MDF? Chip board typically offers a more budget-friendly alternative compared to MDF.

Post time: 10 月-08-2024