What is Marine Plywood?

Marine plywood is a specialized type of plywood, is designed for use in environments where exposure to moisture is a constant factor. Unlike regular plywood, marine plywood is made from durable wood species and bonded with waterproof adhesives, making it ideal for applications like boat building, docks, and outdoor furniture. Its unique manufacturing process ensures it withstands moisture without warping or delaminating, a critical feature for any material used in marine or outdoor settings.

How Waterproof is Marine Plywood?

Understanding Marine Plywood Waterproof Qualities

Marine plywood stands out for its exceptional waterproofing capabilities. This is primarily due to two factors: the type of wood used and the adhesives employed in its construction. Woods like Douglas fir or Western Larch are commonly used, known for their natural resistance to moisture. Additionally, the layers of wood are bonded with waterproof phenolic adhesives, ensuring that the plywood remains intact and functional even when submerged in water. This makes marine plywood an ideal choice for boats, docks, and other marine structures.

Comparing Waterproofing with Other Plywoods

When compared to standard plywood, marine plywood’s waterproofing is far superior. Regular plywood may have voids in its layers and is usually bonded with adhesives that are not waterproof. This can lead to water seepage, swelling, and eventual breakdown of the material. In contrast, marine plywood’s construction ensures a void-free core and the use of waterproof adhesives, providing a much more durable and long-lasting solution for applications exposed to water.

What is the Difference Between Marine Plywood and Normal Plywood?

Core Composition and Quality

The primary distinction between marine and regular plywood lies in their core composition and quality. Marine plywood is made with higher quality veneers, free from defects like knots or splits, which can compromise the strength and integrity of the plywood. This high-quality core is essential for applications where strength and durability are paramount.

Adhesive Differences

Another significant difference is the type of adhesive used. Marine plywood uses phenolic or melamine formaldehyde adhesives, known for their superior water-resistant properties. These adhesives ensure that the layers of the plywood remain firmly bonded, even under prolonged exposure to moisture. In contrast, regular plywood often uses urea-formaldehyde adhesives, which are less resistant to water and can break down over time when exposed to moisture.

Usage and Applications

The usage and applications of these two types of plywood also differ greatly. Marine plywood is specifically designed for environments where it will be exposed to moisture consistently, such as in boat building or outdoor furniture. Normal plywood, on the other hand, is more suited for interior applications where exposure to moisture is minimal, such as in furniture making or indoor paneling.

Is Marine Plywood Strong?

Assessing the Strength of Marine Plywood

Marine plywood is not only waterproof but also exceptionally strong. The high-quality wood veneers used in its construction contribute to its strength and durability. The cross-laminated structure of the plywood layers adds to its strength, distributing the load and stress evenly across the panel. This makes marine plywood highly resistant to cracking, bending, and warping, essential qualities for materials used in demanding environments like marine construction.

Comparison with Exterior Grade Plywood

While exterior grade plywood is also designed for outdoor use, it does not match the strength and durability of marine plywood. Exterior grade plywood may be suitable for outdoor furniture or signage, but for structures that require the utmost in strength and durability, especially where constant moisture exposure is a factor, marine plywood is the superior choice. Its construction ensures that it can withstand harsh environmental conditions without losing its structural integrity.

Marine Plywood Versus Phenolic Plywood: A Comparative Analysis

Understanding Phenolic Plywood

Before diving deeper into the nuances of marine plywood, it’s essential to understand its close relative, phenolic plywood. Phenolic plywood, often recognized for its black or brown phenolic film, is a type of plywood coated with a phenolic resin impregnated paper. This coating not only gives it a distinctive appearance but also enhances its resistance to moisture, chemicals, and wear and tear. It’s commonly used in applications requiring a durable, smooth surface and resistance to harsh conditions, such as concrete formwork, industrial flooring, and outdoor furniture.

Comparative Waterproofing

While both marine and phenolic plywoods are designed for high moisture resistance, their waterproofing capabilities differ slightly. Marine plywood’s core is made of water-resistant woods and bonded with waterproof adhesives, making it suitable for direct and prolonged water exposure. Phenolic plywood, with its resin-coated surface, offers excellent resistance to moisture on its surface, but if the core is not made with similar waterproof standards as marine plywood, it may not withstand prolonged submersion as effectively.

Strength and Durability

In terms of strength, marine plywood generally has an edge due to its high-grade wood veneers and the strength-enhancing cross-lamination process. Phenolic plywood, while strong and durable, primarily gains its strength from the phenolic resin coating. This coating is highly resistant to wear, making it ideal for high-traffic areas. However, for structural applications where the core strength is paramount, waterproofing plywood is often the preferred choice.

Marine Plywood in Outdoor Construction

Outdoor Applications of Marine Plywood

Marine plywood’s resistance to water and its inherent strength make it a prime candidate for various outdoor construction projects. It is extensively used in boat building, not only for its waterproof properties but also for its ability to maintain structural integrity under stress. Beyond marine applications, it’s also used in building outdoor furniture, decking, and structures like pergolas and gazebos, where exposure to the elements is a given.

Advantages Over Other Exterior Grade Plywoods

While exterior grade plywood is often considered for outdoor applications, phenolic plywood offers several advantages. Its superior waterproofing ensures a longer lifespan and less maintenance, especially in climates with significant rainfall or humidity. Additionally, its strength makes it more resistant to warping and bending, essential in maintaining the structural integrity of outdoor constructions.

Innovations and Sustainability in Marine Plywood Production

Technological Advances

The production of marine plywood has seen significant technological advances in recent years. Manufacturers are continually improving the quality of the adhesives to enhance the waterproofing and bonding strength. Additionally, new methods in veneer selection and treatment are being employed to ensure the highest quality and uniformity in the plywood sheets.

Sustainability and Environmental Considerations

Sustainability is a growing concern in the production of exterior grade plywood. Many manufacturers now focus on sourcing wood from responsibly managed forests, ensuring that their products do not contribute to deforestation. Moreover, there is an increased emphasis on using eco-friendly adhesives and reducing the carbon footprint of the manufacturing process.

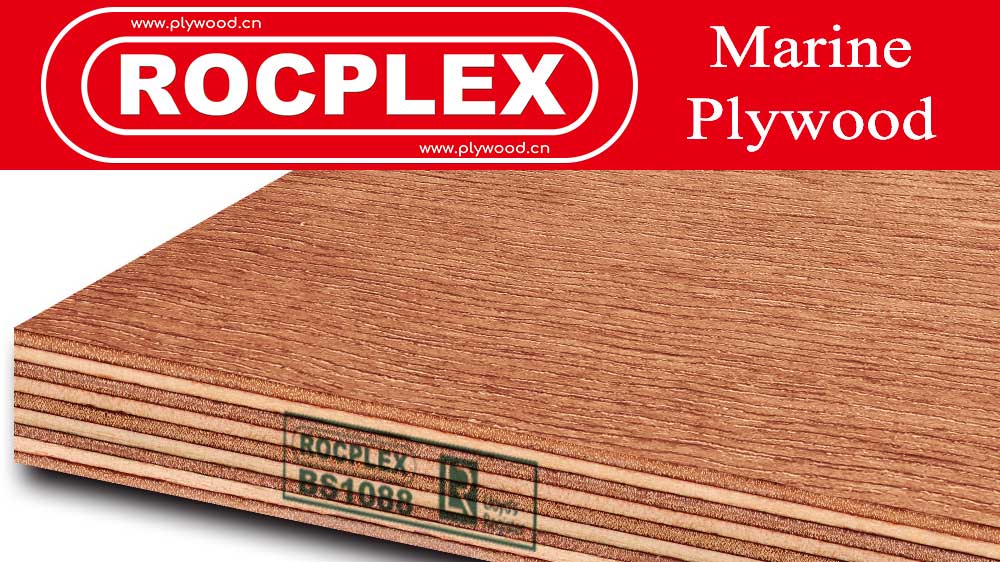

Marine Plywood Certification and Standards

Importance of Certification

Certification plays a crucial role in ensuring the quality and reliability of marine grade plywood. Certifications like the British Standard (BS) 1088 specify the requirements for high-quality marine ply, including the type of wood, adhesive quality, and manufacturing process. Consumers and industry professionals often look for these certifications as a guarantee of the product’s suitability for marine and high-moisture environments.

Adhering to International Standards

Marine plywood manufacturers must adhere to various international standards to ensure their products are suitable for global markets. These standards dictate everything from the species of wood used to the testing methods for determining moisture resistance and strength. Compliance with these standards not only ensures a high-quality product but also fosters trust among consumers and industry professionals.

The Role of Waterproofing Plywood in Marine Applications

Significance of Waterproofing

In the context of waterproofing plywood, waterproofing is not just a feature but a necessity. This specialized plywood is often used in conditions where it is exposed to water for prolonged periods. The waterproofing ensures that the plywood does not absorb water, swell, or degrade over time, maintaining its structural integrity and longevity.

Techniques and Materials

The waterproofing of phenolic plywood is achieved through the use of high-quality, water-resistant adhesives. Such as phenolic resins, and the selection of naturally moisture-resistant wood species. Advanced manufacturing techniques further enhance this property, making sure that the plywood can withstand harsh marine environments.

Marine Plywood in Boat Building and Repairs

Boat Building Applications

Marine plywood is a popular choice in boat building due to its strength, lightweight nature, and resistance to water. It is used in constructing everything from small dinghies to large yachts, offering a reliable material that can be shaped and fitted easily, yet hold up against the stresses of water travel.

Repair and Maintenance

For boat repairs and maintenance, exterior grade plywood is indispensable. Its compatibility with a range of finishes and sealants makes it ideal for patching holes or replacing damaged sections. Boat owners and repair shops prefer marine grade plywood for its ease of use and the fact that it matches the performance of the original materials used in boat construction.

Comparing Marine Ply with Regular Plywood in Various Applications

Home Construction and Remodeling

In home construction and remodeling, marine ply is often used in areas prone to moisture, such as bathrooms, kitchens, and outdoor spaces. Its waterproof nature makes it a better choice than regular plywood, which may warp or deteriorate in such environments.

Commercial and Industrial Use

In commercial and industrial settings, waterproofing plywood is valued for its durability and strength. It’s used in creating outdoor signage, constructing platforms, and in manufacturing settings where moisture resistance is required.

Future Trends and Developments in Marine Plywood

Research and Development

The future of phenolic plywood lies in ongoing research and development aimed at enhancing its properties. This includes exploring new wood species, developing more eco-friendly adhesives, and improving manufacturing processes to increase durability and reduce costs.

Market Growth and Demand

As awareness of the benefits of exterior grade plywood increases, its market is expected to see significant growth. This growth will be driven by its versatility, durability, and the expanding range of applications in both the marine and construction industries.

Marine Ply Durability vs Phenolic Ply

The Unmatched Qualities of Marine Plywood

Reflecting on the comprehensive exploration of marine grade plywood. It’s evident that this material stands out for its unique combination of strength, waterproofing, and versatility. Its ability to withstand harsh environments, coupled with its suitability for a wide range of applications, makes it a top choice for both professionals and hobbyists. As the industry continues to evolve, marine ply remains a steadfast and reliable material, indispensable in various fields.

Marine plywood, with its unparalleled properties and growing applications. Is not just a construction material but a testament to human ingenuity in adapting natural resources for diverse needs. Its ongoing development and increasing sustainability practices highlight its role in a future where durability and environmental consciousness go hand in hand.

Post time: Dec-18-2023